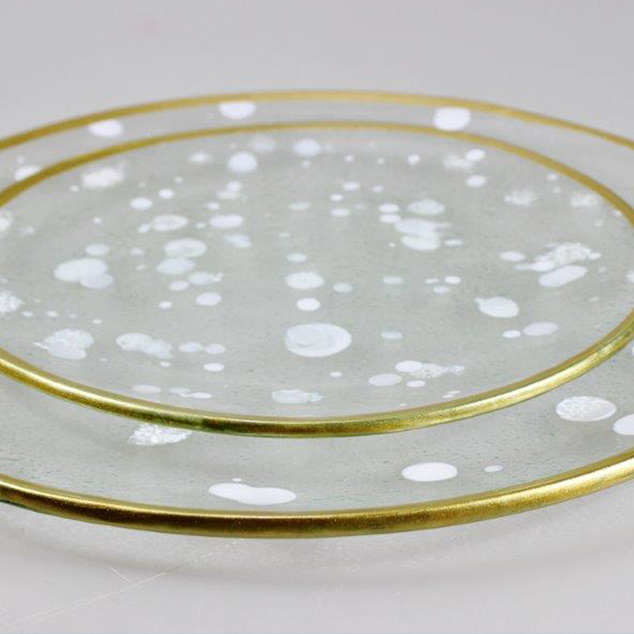

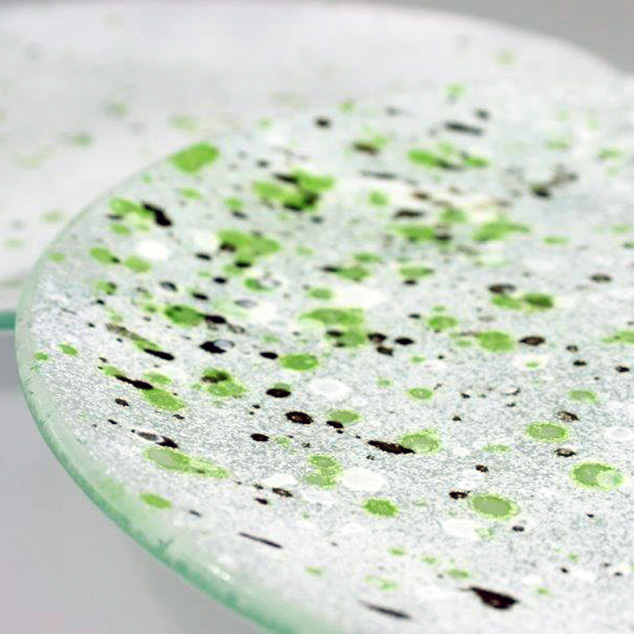

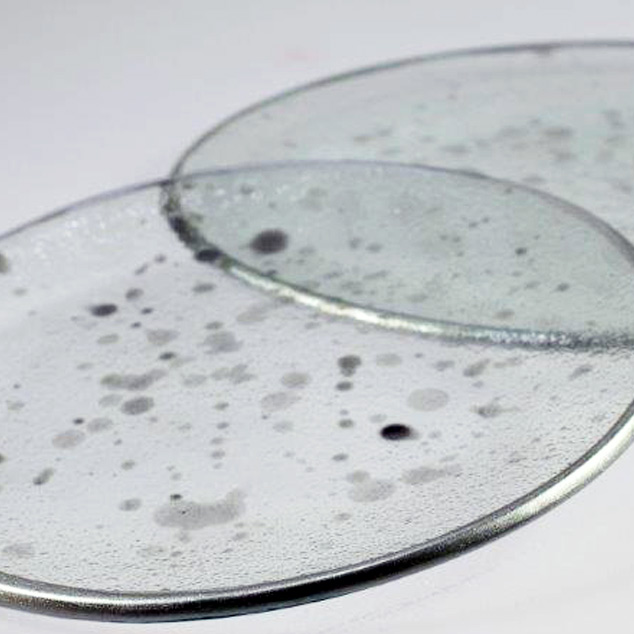

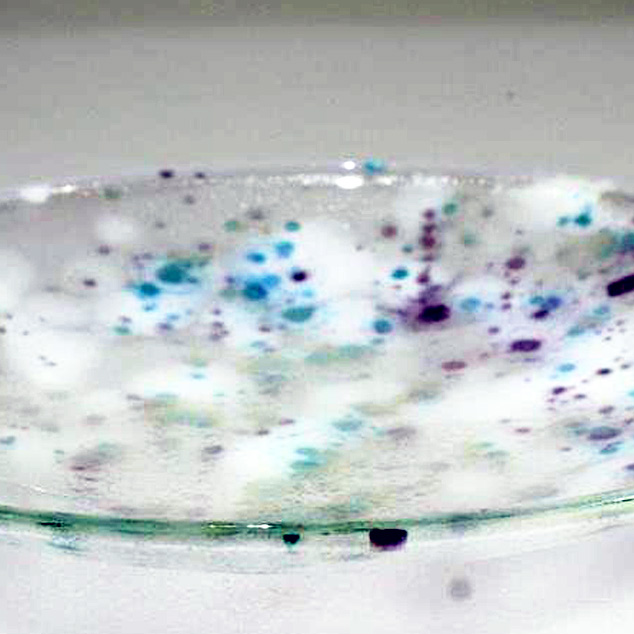

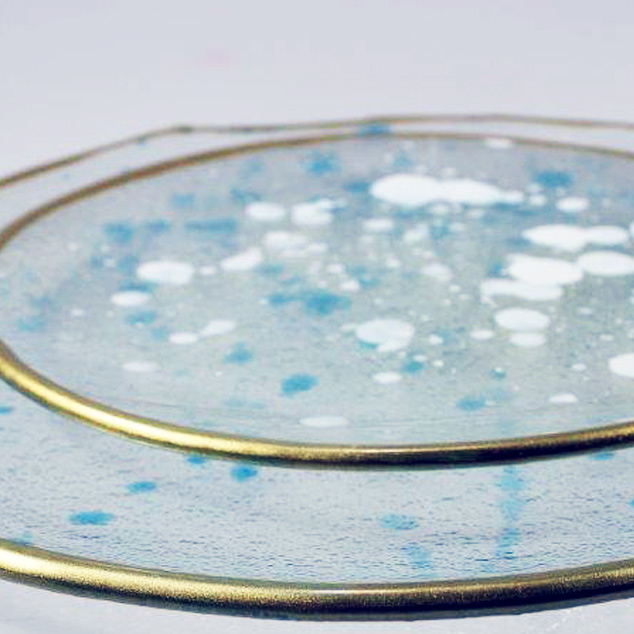

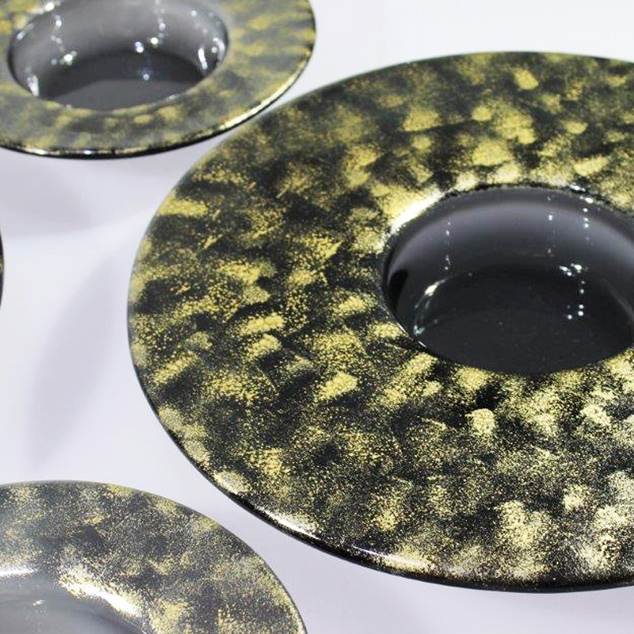

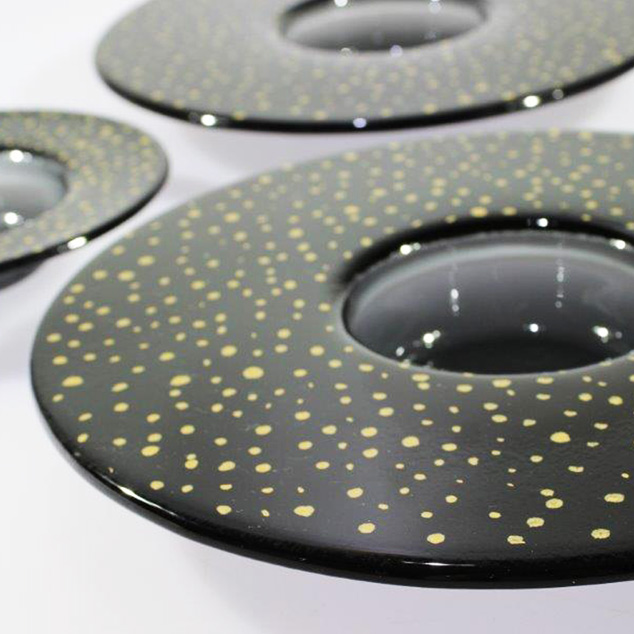

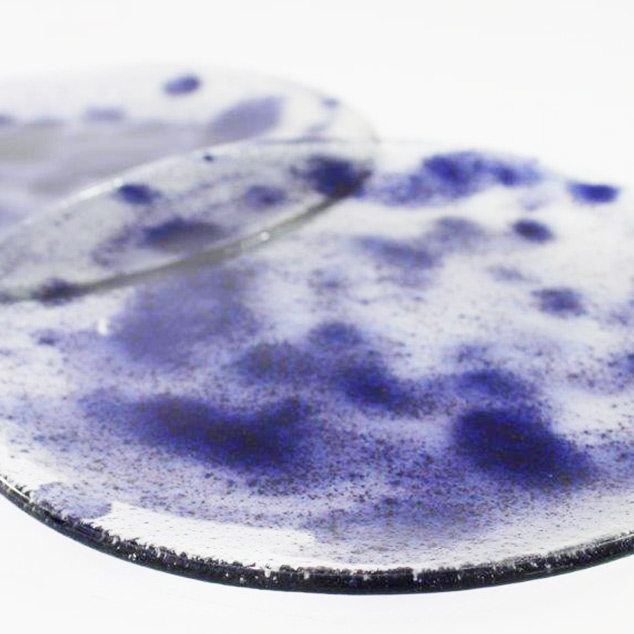

FUSING technology is a glass production method based on fusing flat glasses together and subsequently shaping (“laying”) them at temperatures between 800 and 850°C. We do not process molten glass like ordinary glassworks: our raw material is flat glass.

FUSING technology enables us to produce shapes and colour combinations that other glass techniques do not allow.

Smaller elements are cut by hand from flat glass with a diamond cutter, while larger sizes are cut on a computerised cutting machine that enables precision to within one millimetre. Unused pieces flat glass are recycled into other production processes, meaning that BDK-GLASS produces virtually no waste.

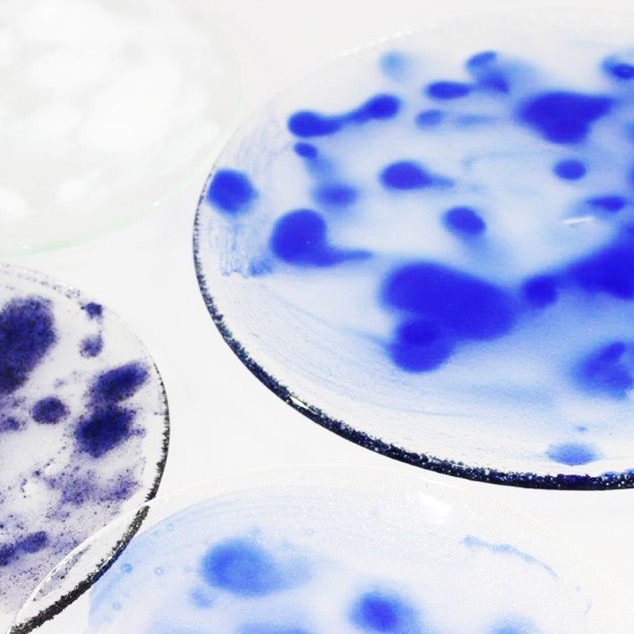

Before the product itself is fused and shaped, it is possible to decorate the glass through various techniques such as painting, sprinkling with shards and frit (glass powder), fusing decals, etc. Following the heat treatment of the products, we can add other design elements through sandblasting, grinding, and other techniques.